Our Products

FINOLEX TELEPHONE CABLES

Finolex twisted paired cables are best suited for telephone cabling applications. The conductor is made of solid annealed, electrolytic grade high conductivity bare copper. The conductor is insulated with special grade high-density polyethylene with different colours. The insulated cores are twisted with uniform lay to form pairs and are bunched together in such a manner so as to minimise cross talk. In 50 and 100 pair cables the units of 10 and 20 pairs respectively are identified with colour binders and stranded to form the laid up cable. The laid up cable is further jacketed with a grey colour fire retardant (FR) PVC specially formulated and manufactured in-house, with high oxygen and temperature index. The cables can be used for internal telephone wiring in high-rise buildings, offices, factories, hotels, residential complexes, etc. Stringent quality control at every stage, from raw material through manufacturing, up to the finished product guarantees high quality.

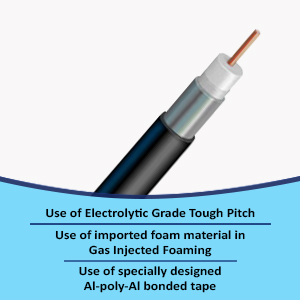

- Central conductor is made of 99.97 % pure solid copper manufactured in house. It is insulated with Nitrogen gas injected physical foam dielectric manufactured from imported polyethylene, which enhances the foaming upto 70%, which leads to lower and uniform attenuation.

- This also ensures that the insulation is free from impurities and the foam cell structure is uniform across entire length. The secondary conductor is made of specially designed poly-aluminum tape bonded with sufficient overlap on dielectric.

- The second shield is of imported aluminum alloy wire braiding with high tensile strength and has more than 60% coverage suitably flooded with jelly so that the weather effect on conductors is negligible.

- The outer jacket that has specially formulated PVC manufactured in-house, is of UV resistant nature, for robust performance and long life. Each coil/ bobbin is tested on computerized Test equipment for Attenuation, Impendence and SRL upto 1GHz.

Features :-

↑